FEATURES

1. The main control circuit adopts Japanese Panasonic PLC,Taiwan delta frequency converter, Italian delijie color code tracking photoelectric joint control to ensure the high-precision implementation of the system control program.

2. Innovative design of double valve segmentation system, simple and convenient valve membrane installation, stable operation and high segmentation accuracy.

3.Excellent human-machine interface and temperature control module, clear and intuitive interface, convenient operation.

4.Speed display, length display, automatic count, batch count, fault display, no material alarm, clear and intuitive temperature alarm screen, simple and convenient operation.

5. The electric oil pump is equipped with centralized automatic oiling and lubrication, which is safe and reliable.

6. The whole machine is driven by six Super Thick connecting rods of three reducers, three layers of pulling film, discharging by double frequency conversion decelerating motor and receiving by double station frequency conversion decelerating motor, which can reduce downtime, have high speed, high pressure and accurate accuracy.

7. lt adopts multi-channel electronic ruler to control the frequency converter technology, which has a wide range of speed adjustment and realizes continuous stepless speed change, namely, it is set to use and the whole machine is perfectly matched.

8. The discharge chute type photoelectric control synchronous motor can automatically rectify the deviation,reduce the working pressure and reduce the manual error.

9.Double position easy to tear device. double easy to tear knife can be combined at will according to demand, switching is simple and convenient.

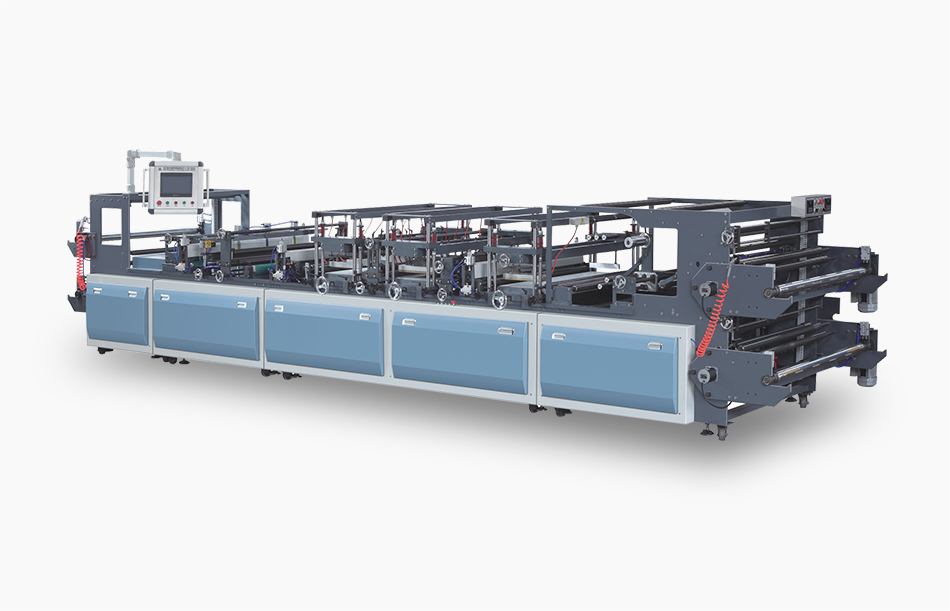

MAIN TECHNICAL PARAMETERS

|

Mold length |

1180mm |

|

Maximum winding diameter |

φ500mm |

|

Diameter of inflatable shaft |

φ74mm |

|

Packaging film material |

PE+PA coextrusion film |

|

Receiving station |

2 bits |

|

Maximum receiving diameter |

φ600mm |

|

Qualified rate |

≥99% |

|

Column velocity |

25-80 times/min |

|

Sealing pressure |

7500N |

|

Die width |

395mm |

|

Machine noise |

55db |

|

Total installed capacity of the machine |

20kW |

|

Total machine weight |

4500kg |

|

Machine dimensions |

8360mm×1800mm×1900mm |

|

Air source |

Rated flow 0.6m3/min rated pressure 0.6-0.8MPa |

Obtained a number of national invention and utility model patents